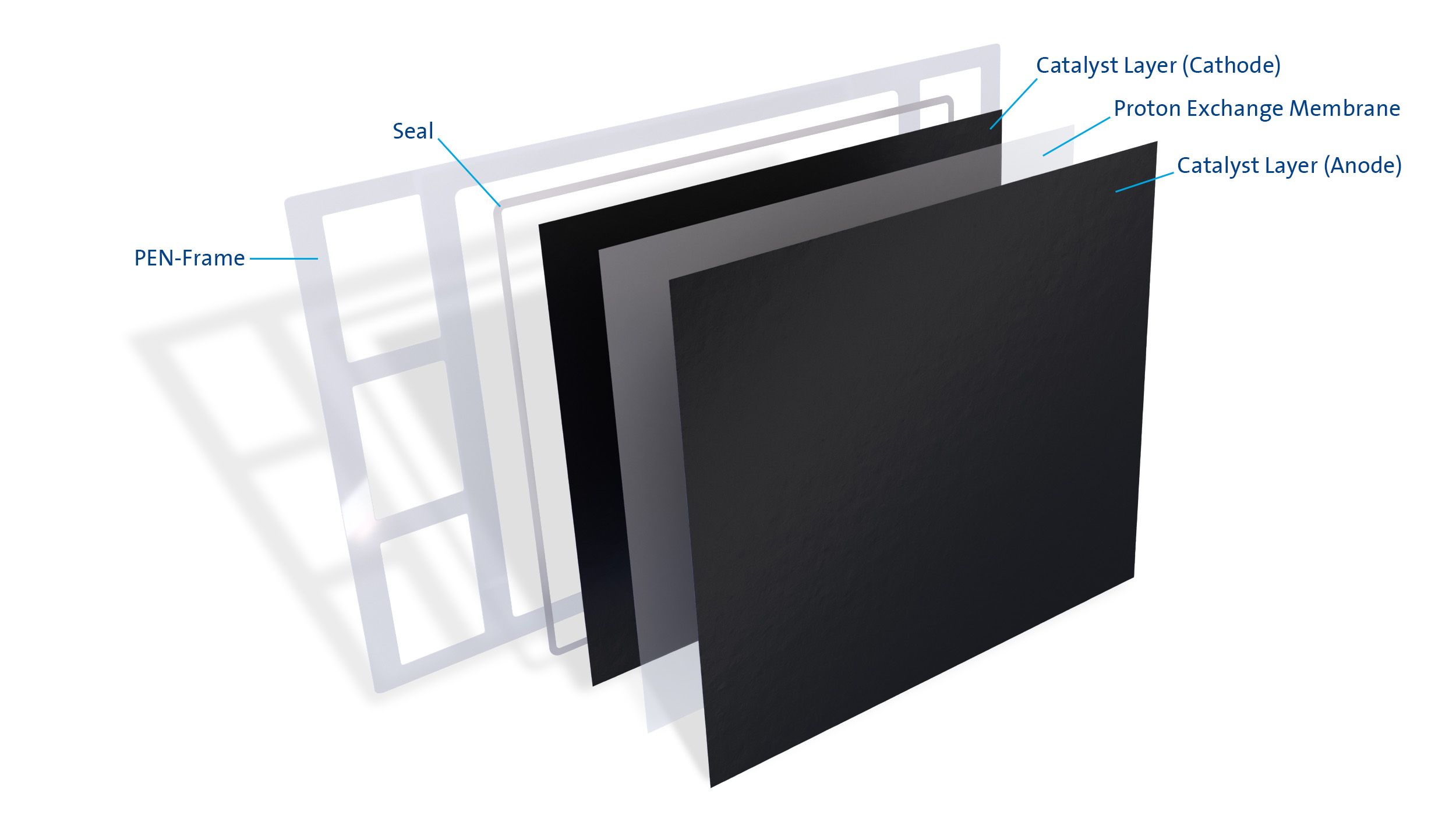

质子交换膜 (PEM) 燃料电池催化剂及催化剂涂层膜(CCM)

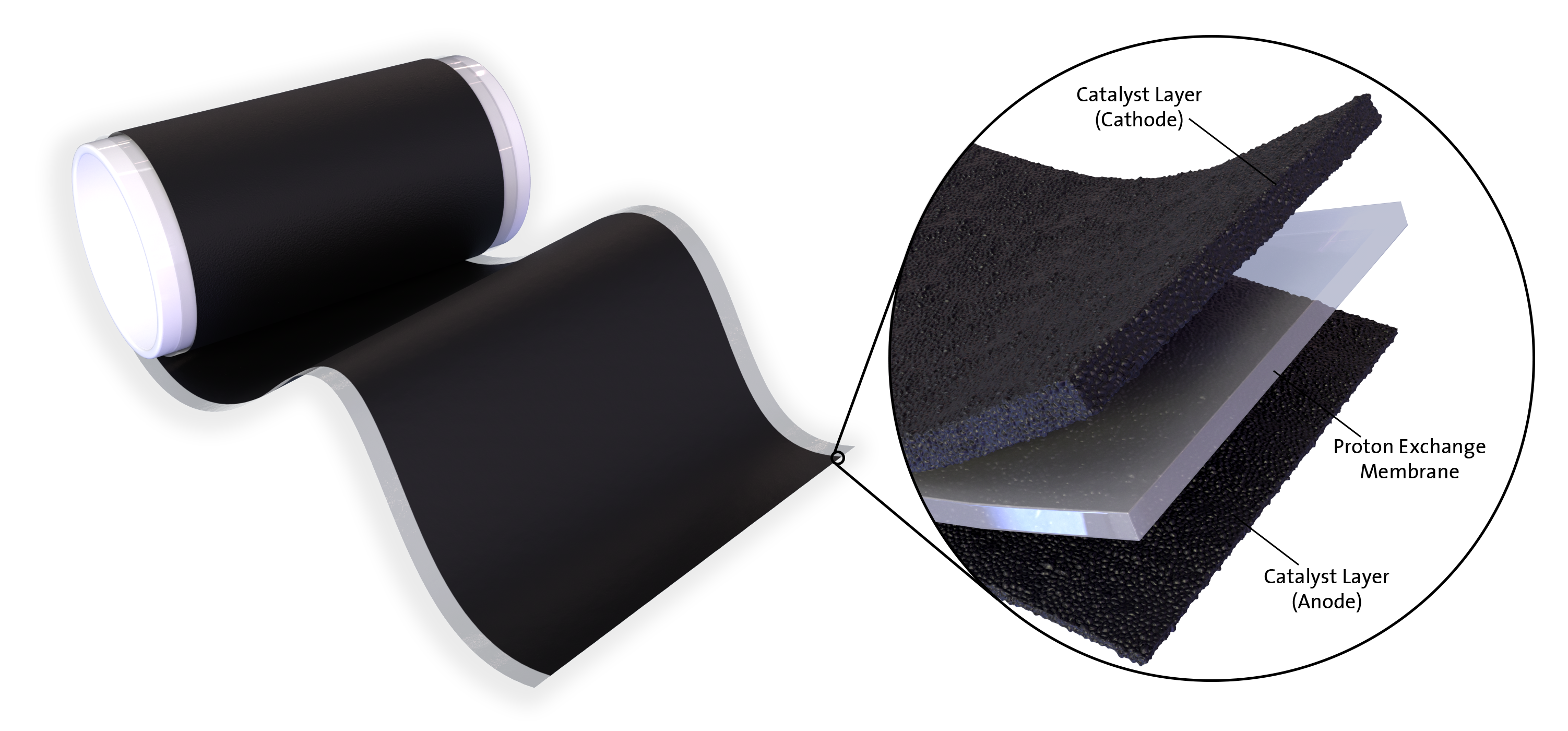

质子交换膜(PEM)燃料电池将氢和氧转化为水,并在此过程中释放能量。燃料电池的核心是两面都涂有铂基催化剂的质子交换膜(催化剂涂层膜,CCM)。

PEM燃料电池与燃料电池运行

质子交换膜(PEM)燃料电池将氢和氧转化为水,并在此过程中释放能量。燃料电池的核心是两面都涂有铂基催化剂的质子交换膜(催化剂涂层膜,CCM)。

PEM燃料电池可用于不同的移动和固定设施,例如储能设施、叉车、轻型和重型卡车。在交通运输领域,燃料电池汽车与纯电动汽车存在部分竞争。然而,更长的续航里程和显著缩短的加氢时间,使氢燃料电池汽车成为长途和重型运输工具的首选。

由于世界各国共同承诺减少二氧化碳排放,建立碳中和社会,人们普遍认为PEM燃料电池会迎来强劲增长。这将使燃料电池汽车在全球范围内部署,并大大降低整车成本。

贺利氏为不同燃料电池应用的CCM阴极和阳极提供贵金属催化剂,其中包括:

- 固定设施

- 叉车

- 乘用车

- 重型运输工具

- 火车和公共汽车

贺利氏的PEM燃料电池催化剂产品组合

在PEM燃料电池中,贺利氏的铂基催化剂有助于促进燃料电池电堆中的两个电极反应,在各种条件下高效地从氢气和氧气产生电能和水。

我们的产品包括具有不同贵金属负载量的PEM燃料电池催化剂。

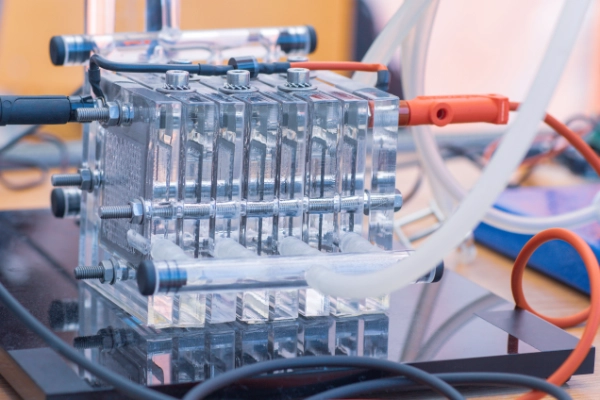

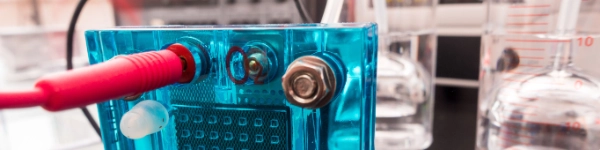

为了找到满足您需求的解决方案,我们能够在设备齐全的现场实验室和测试中心进行实测。

| 催化剂 | Actydon | Pt C100 + Actydon | Ir 80 X |

Actydon | Pt C700 | Actydon | Pt M700 | Actydon | Pt 50 K700 |

|---|---|---|---|---|

| 说明 |

石墨化碳材料上的铂含量为 20 至 40 wt.% - |

高表面积碳上 20 至 60 重量百分比的铂 | 高比表面积碳上 40 至 50 重量百分比的稳定铂 | 高比表面积碳载体铂钴合金催化剂 |

| 亮点 | 高电池反向耐受性 > 8000 秒(15 μgIr/cm²) (~75 秒,不含 OER 添加剂)** |

优化铂表面利用率 /高 ECSA | 提高铂溶解稳定性 |

更高的铂溶解稳定性 |

| ECSA [m²/gPt] | > 40 | > 70 | > 60 | > 45 |

| 电池电压 @ 0.1 A/cm² (CCM)* [V] |

~ 0.80 | ~ 0.84 | ~ 0.84 | ~ 0.84*** |

| 获取更多信息 | 在线订购 | 获取更多信息 | 获取更多信息 |

* 汽车条件 **直至 -1.25 Vcell ***在0,2mgpt/cm2

联系贺利氏PEM燃料电池催化剂专家

| Actydon | CCM 01 | Actydon | CCM 02 | |

|---|---|---|

| Highlight | High efficiency, flexible humidity range, high durability |

High current density, high durability |

| Cell voltage* @ 0.1 A/cm² [V] | 0.88 | 0.86 |

| Current density* @ 0.65 V [A/cm2] | 1.9 | 2.0 |

* Differential setup (RH 95%, 80 °C)

-

Efficiency: Enhanced Catalyst efficiency.

-

Durability: Extended operational lifespan with minimal degradation.

-

Automation: Highly automated roll-to-roll production processes.

-

Sustainability: Manufacturing with efficient use of resources.

-

Circularity: Holistic precious metals sourcing and recycling concept.

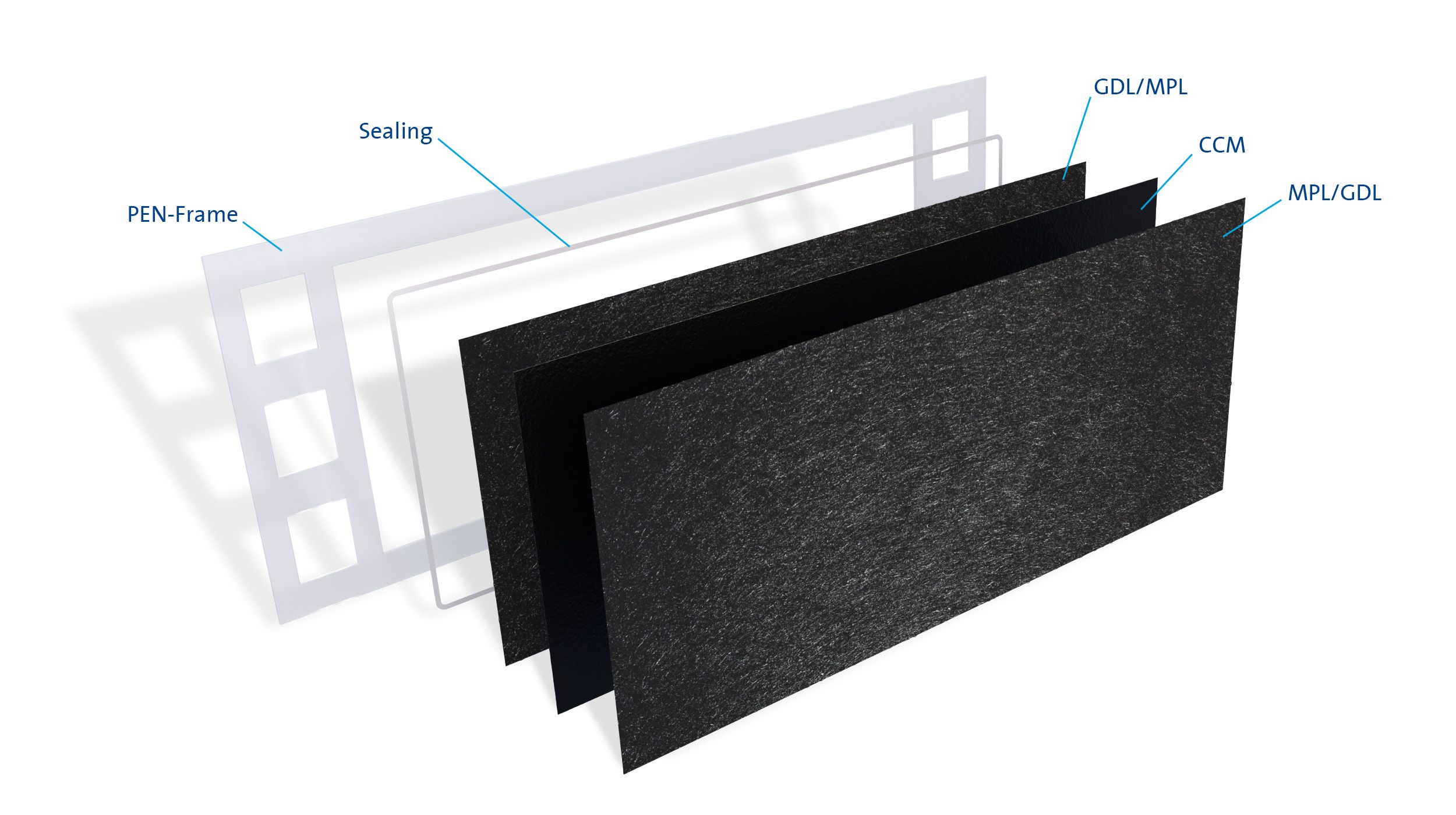

Membrane Electrode Assembly (MEA) for Fuel Cells

All high-volume catalyst-coated membrane (CCM) variants are also available as membrane electrode assembly (MEA) configurations utilizing the know-how of FEPS in sealing technologies and gas diffusion layers (GDL). The available MEA7 structure is a 7-layer structure, compried of CCMs laminated with advanced gas diffusion layers (GDLs) and customized frame. A tailored sealing solution integrates the entire cell architecture into a precisely engineered polymer frame, ensuring easy handling and efficient integration into fuel cell stacks. This sealing approach effectively eliminates gas crossover, contributing to extended operational lifetimes.

By adopting Heraeus Precious Metals’ high-volume MEA program, you gain access to the full performance advantages of the unique CCM technology while minimizing the cost for MEA manufacturing equipment. This strategy enables a reduction in the Total Cost of Ownership (TCO) for PEM fuel cells through three key avenues: a) utilization of high-performance, durability-enhanced catalysts; b) operational cost savings via the scalable production facility; and c) sustainable material management through closed-loop recycling, covering both production waste and end-of-life components.

-

Activity: Engineered GDL and MPL structures for enhanced mass transport properties.

-

Assembly: The MEA7 features a structurally reinforced design with an integrated frame, streamlining the fuel cell stack assembly process.

-

TCO: Reduction of the total cost of ownership (TCO) of PEM fuel cells through performance- and stability-optimized catalysts and electrodes, as well as expertise in metal management and recycling

-

Efficiency: Innovative precious metal deposition results in optimal platinum utilization.

-

Durability: Long lifetime for your application by using electrode layers designed for best stability and reliability.

-

Industrial Scale: Proven industrialization competence in electrochemistry. Established and highly efficient manufacturing technology with integrated quality controls.

Customized CCM and MEA

CCMs and MEAs can be customized to align with the specific requirements of your application, ensuring optimal performance where it is most critical. Leveraging Heraeus Precious Metals’ proprietary catalyst manufacturing technology, you are enabled to maintain outstanding quality while keeping production costs low. This allows for exceptional efficiency and extended operational life, driven by highly active and durable catalyst layers.

These modular, multi-layer assemblies are engineered for high-volume manufacturing and incorporate proprietary sealing materials that provide long-term protection for the active regions throughout all MEA layers. Integrated into a precision frame using a patented lamination technique, they enable simplified handling and streamlined assembly. Heraeus Precious Metals’ MEAs deliver consistent, high-efficiency performance even under demanding, heavy-duty conditions, maintaining reliability across a broad spectrum of humidity, temperature, and pressure ranges—without compromising service life.

By combining extensive fuel cell design expertise with advanced production capabilities, the tailored MEA solutions are both cost-efficient and performance optimized. Heraeus Precious Metals focus is on helping customers minimize fuel consumption and reduce maintenance costs across diverse application environments.

-

Cost Efficiency: Economical manufacturing processes that reduce overall production expenses.

-

Longevity: Extended performance life for reliable, long-term operation.

-

Customization: Tailored solutions designed to meet specific application requirements.

-

Durability: Ultra-stable catalyst layers designed for prolonged activity and minimal degradation.

-

Application Focus: Designs optimized to align with the functional demands of each use case.

| Actydon | CCM 01, Actydon | CCM 02 | Actydon | MEA 01, Actydon | MEA 02 | |

|---|---|---|

| Membranes | Various thicknesses and additives | Various thicknesses and additives |

| Dimensions | Variable coating widths (Max: 460mm) |

Customized solutions (available on request) |

| Delivery Formats | CCM roll or MEA sheets (samples available) | CCM roll or MEA sheets (samples available) |

To deliver this superior level of reliability at industrial scale, Heraeus Precious Metals and Freudenberg e-Power Systems have combined their unique capabilities in a technical partnership: Advanced precious metals expertise meets leading-edge system oriented process know-how, delivering a complete loop from metal sourcing and financing, product supply, to recycling of platinum group metals.

促进燃料电池运行的催化方案——电厂配套设施

燃料电池将燃料和氧化剂的化学能直接转化为电能,是能源转换——特别是用作可持续分布式电源时——的一项关键技术。

根据工作原理、电解质、工作温度或所用燃料的不同,可以将燃料电池技术分为不同的类型。燃料电池技术不同,对支持设备的要求也不尽相同,这些设备首先要让电池能够作为一种环保可靠的能源发挥作用。

除了提供 PEM燃料电池催化剂,贺利氏贵金属还拥有高效的气体处理与减排催化剂技术,可以有效应对上述挑战。

在燃料处理方面,贺利氏为催化重整、水煤气变换或气体净化提供优先氧化(PROX)或选择性甲烷化等催化方案,并且可以根据独立分布式系统的运行需要量身打造。如需了解有关贺利氏非均相催化剂的更多信息,请访问 催化剂选择器

凭借在 减排催化剂 领域长期积累的丰富经验,贺利氏贵金属能够为废气处理以及催化燃烧能量回收生产高效耐用的催化剂。

每种燃料电池技术都有各自的优点和局限性,这也最终决定了各自适合的应用。凭借本体催化剂和定制催化涂层,贺利氏贵金属为您提供大力支持,确保电厂配套设施完美适配您的特殊应用。

联系贺利氏燃料电池运行催化方案专家

联系我们

Press and News

赫拉埃乌斯贵金属公司的迈克尔·乔治博士与克里斯蒂安·格鲍尔博士探讨了氢燃料电池在重型车辆材料发展中可能发挥的作用。